Challenge

The challenge was to digitize the tire inspection process. The client offers tire maintenance service for its customer’s fleet of trucks. Prior to this digital transformation, the inspector in charge visited each fleet, took the depth and pressure measurements of the tires, and wrote down the values on a piece of paper. When he returned to the office, he entered the information in a spreadsheet on the computer and only then was the data on the condition of the tires available to evaluate if it was time to perform a retread and send the results to the clients.

Truck fleets are often located in open spaces and away from the city. This meant that it took too long for the information to be available. Sometimes the inspector could take up to 3 days before he returned to the office. Furthermore, this was a completely manual process that took effort and carried the risk of human error.

Our Solutions

With the aim of making work more efficient and facilitating access to information, they teamed up with Rootstack to develop a tire retreading automation software solution. Our team of software developers fully adapted to the client's needs.

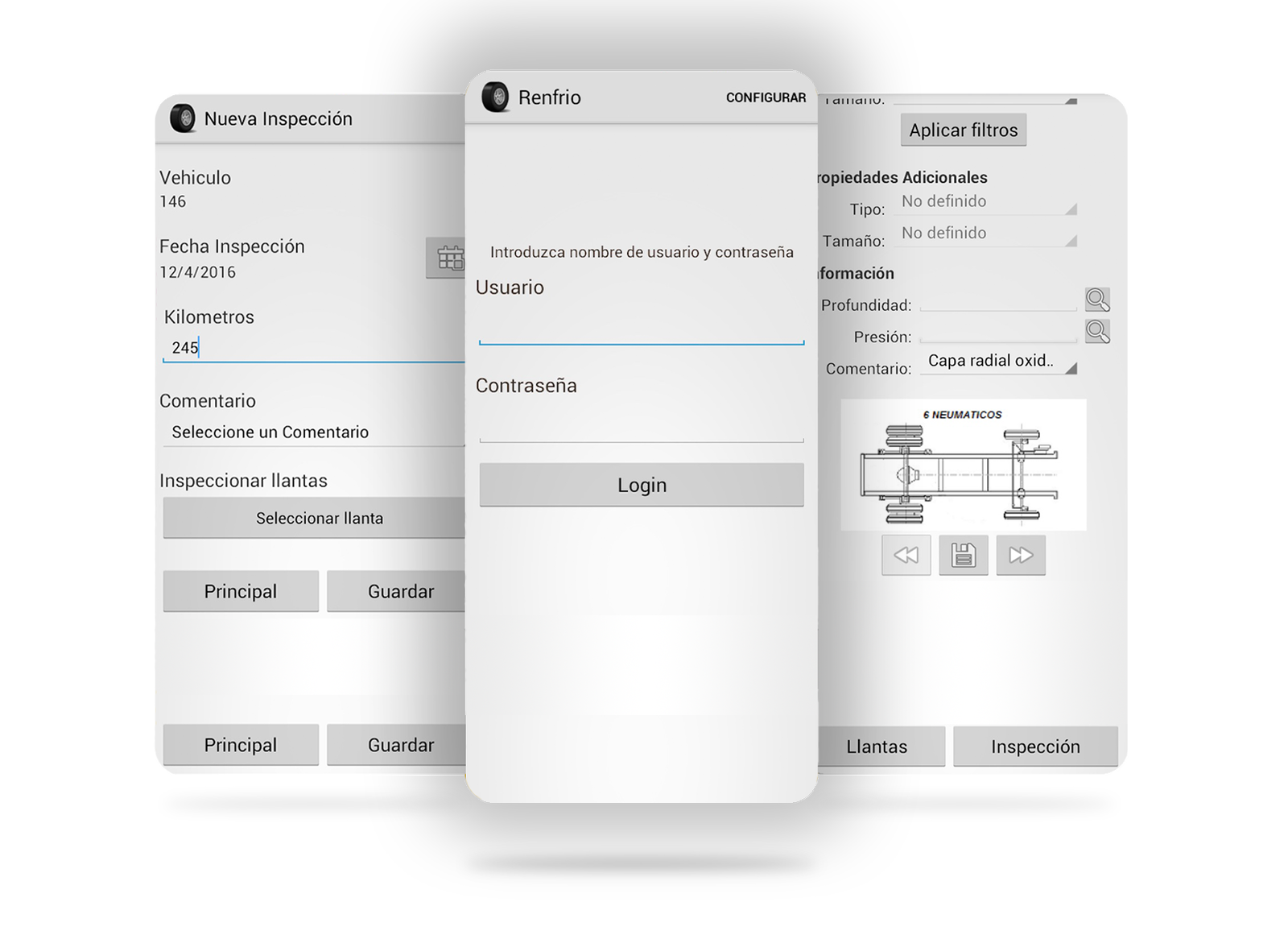

A mobile application was developed with a Bluetooth connection to the device that the inspector uses to measure the depth and pressure of the tires. When taking the measurements, the values are automatically recorded in the App, assigning the truck and tire in question. The inspector selects the truck to be inspected in the App, and automatically knows how many tires it has and what measuring order to follow.

Also, an offline functionality was implemented to guarantee the app’s correct operation no matter how far the fleet is. When the device reconnects to the internet, the information is then sent to the server.

A web application was also developed to receive the data that is recorded in the mobile app and generate reports that graphically show the tire’s condition. When the app’s information is synchronized with the web, an email is sent to the client notifying that the inspection has been carried out and reporting the results. Each tire has previously configured ranges of values and crossing the inspection values with these conditions indicates which tires should be retreaded. Users were created on the web so that each Maxillantas client can access real-time and historical information.

Rootstack applied its expertise in advanced management systems to help Maxillantas modernize its processes, including cutting-edge technology to offer its clients a high specification and quality service.